Why Energy Management Matters for Your Business

In today’s business landscape, energy management is more than just a buzzword—it’s a crucial competitive advantage. For industrial and commercial operations, energy costs make up a substantial portion of overall expenses, while also contributing significantly to carbon emissions.

By reducing energy usage without compromising productivity, companies can achieve substantial savings, gain a competitive edge, and enjoy environmental benefits such as reduced carbon emissions—a true win-win. So, where should you begin to uncover these energy-saving opportunities?

1. Understand Your Energy Cost & Carbon Emissions

Your business’s energy footprint encompasses all fuel sources consumed, including electricity, natural gas, fossil fuels, and biomass. By finding ways to use less energy while achieving the same results, businesses can significantly reduce both operational costs and carbon emissions. For example, by implementing an Energy Management System (EnMS), you could realize up to 20% savings through simple maintenance and low-cost upgrades. Furthermore, additional equipment or technology enhancements can provide an extra 10-20% in savings. Ultimately, effective energy management enables organizations to lower their energy bills and reduce carbon emissions by over 35%.

2. Accelerated Energy Management System – The EnFana Difference

At EnFana, our focus is on implementing energy-saving opportunities that require minimal capital investment while delivering a rapid return on investment. By using our accelerated energy management program, we embed a Continuous Energy Improvement (CEI) culture directly within your organization. Additionally, we integrate seamlessly with your team to complete work more efficiently, allowing us to deploy an energy management system in just a few months—a process that would typically take around two years.

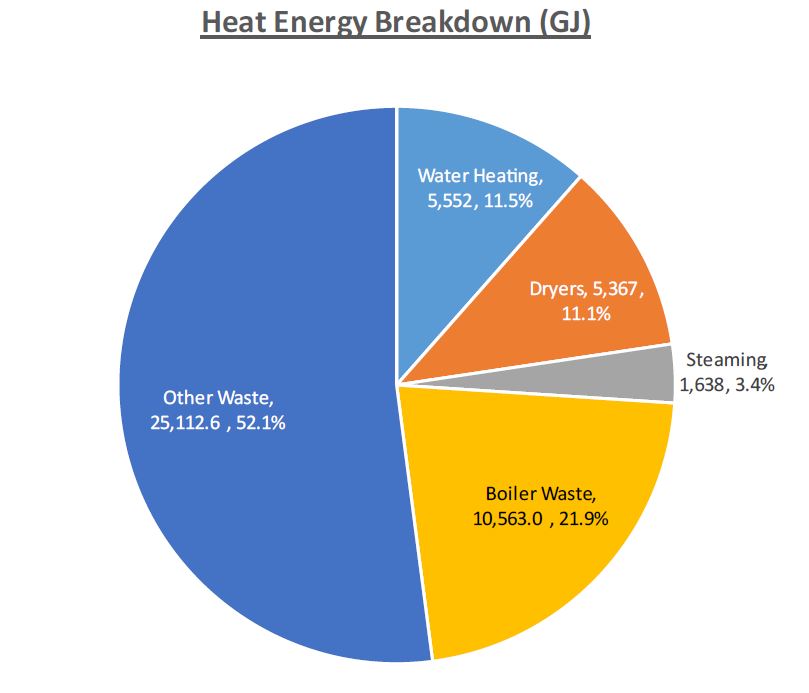

Case Study – Rice Processing Mill

A 305,000 sq. ft. rice processing mill employing 150 people had a total energy cost of $383,000, with annual carbon emissions of 612.6 tCO2/year. Seeking to reduce operating costs and gain a competitive advantage, the facility partnered with EnFana’s. Over seven months, EnFana helped the organization strategically reduce energy consumption.

- Yield annual savings of $53,223 (13.9% of energy cost)

- Reduce electricity consumption by 15.3%

- Cutting Biomass consumption by 11.3%

- Decreasing GHG emissions by 11.7% (644 tCO2/year)

What Is Continuous Energy Improvement (CEI)?

Imagine a business where energy-saving practices are integrated into every task. In this environment, employees routinely turn off unused equipment, closely monitor HVAC settings, and rely on checklists to keep energy consumption under control. As a result, the entire organization becomes invested in this shared goal, fostering a culture in which everyone actively contributes to energy efficiency.

This culture is exactly what an energy management system, such as the ISO 50001 standard, seeks to cultivate within organizations. Essentially, Continuous Energy Improvement (CEI) focuses on embedding energy awareness into daily operations, ensuring that savings are sustained over time rather than achieved through one-off projects. Moreover, this sustainable approach incorporates regular energy reviews, life cycle cost evaluations for equipment comparisons, and team-based accountability, all of which work together to meet both productivity and energy goals.

Who can Benefit from Energy Management System (EnMS)

Do you feel that energy bills are impacting your profits, & reducing them can give you an edge? If yes, you can benefit from an energy management program. CEI is ideal for Industrial or commercial facilities looking to:

- Lower operational costs

- Reduce environmental impact (carbon emissions)

- Save energy (electricity, natural gas, fossil fuel etc.)

- Gain a competitive edge by reducing product or service cost

- Preparing for the ISO 50001 Ready program or the ISO 50001 certification

How to Deploy an Energy Management System (EnMS) – The Accelerated Approach

To implement an Energy Management System (EnMS) and foster a culture of Continuous Energy Improvement (CEI), structured planning and support are essential. With EnFana’s accelerated five-step program, your business can navigate this transition smoothly, as our program addresses common challenges at each step. Additionally, our accelerated EnMS program is both suitable and budget-friendly for small to medium-sized enterprises, making it an accessible solution for businesses aiming to improve energy efficiency.

Stage 1: Calculate Energy & Carbon Footprint

The first step is understanding how and where energy is used throughout your operation. This baseline provides crucial insights for targeted improvements.

In Stage 1, Our Team Will:

Common Challenges & EnFana’s Approach

- Challenge: Uncertainty if you are using more energy compared to competitors

Solution: EnFana provides energy and carbon footprint reports and industry benchmarking, helping you estimate room for improvement. - Challenge: Lack of clarity on where most energy is used

Solution: We work with your team to pinpoint major energy consumers, allowing for focused improvements. - Challenge: Utility billing structure is complex

Solution: EnFana simplifies utility billing structures and usage patterns, providing insights to better manage and reduce energy costs. - Challenge: Limited staff availability for conducting energy studies and analysis.

Solution: We train your team and integrate energy management practices into daily operations, reducing the need for adding headcount. - Challenge: External contractor services cost a lot of money

Solution: Our EnMS deployment empowers your team with the tools and knowledge needed for effective energy management, removing the need for costly external expertise.

EnFana’s approach integrates energy management systems seamlessly into your daily operations, ensuring energy efficiency becomes a routine part of business without additional staffing or complexity.

Stage 2: Implementing an Energy Monitoring System

Improving any metric starts with ensuring visibility and establishing regular tracking. For continuous improvement, monitoring energy use is essential. By consistently tracking energy metrics, you can identify trends, actively engage staff, and generate enthusiasm around energy-saving goals. In turn, this visibility fosters a culture of accountability and strengthens commitment to sustained success.

In Stage 2 Our Team Will:

Common Challenges & EnFana’s Approach

- Challenge: Energy monitoring system software cost a lot of money

Solution: EnFana provides a budget-friendly, easy-to-use in-house management system tailored for efficient energy monitoring without the heavy expense. - Challenge: Software bugs are costly to fix

Solution: We provide reliable and well-supported software solutions that minimize disruptions, with affordable support to address any issues promptly. - Challenge: No time for managers to report additional metrics

Solution: Our EnMS leverages digital automation to streamline reporting, saving valuable time on tracking business indicators and reducing the manual burden on managers. - Challenge: Training for new energy reporting systems will require a lot of time and money

Solution: EnFana’s system is designed for simplicity, minimizing the training needed and making onboarding fast and cost-effective. - Challenge: Lack of skilled staff to analyze data and drive improvements

- Solution: Our EnMS dashboard includes data analytics reports designed to reduce your staff’s workload.

EnFana’s EnMS deployment makes energy management straightforward, efficient, and accessible, allowing organizations to drive improvements with minimal time, budget, and technical resources.

Stage 3: Identify Energy Cost Reduction Activities

Before diving into the details, let’s examine the typical approach taken by traditional energy firms. Usually, these firms begin at Step 3 by offering clients a Level 1 or Level 2 energy audit. The client pays the fee, and the energy firm spends a few hours to several weeks auditing (depending on the project scope) to produce a comprehensive report with a list of recommended energy-saving actions. While these reports are often presented to management, they frequently end up unused. This is typically due to two main factors:

1. Limited Staff Involvement: Employees are often minimally involved in these audits, so they have little motivation to implement or follow through with the recommendations.

2. Lack of Internal Systems or Skills: Many companies lack the internal systems or expertise necessary to act on the recommendations, leaving suggested changes unaddressed.

Some companies may choose to hire external firms to implement these recommendations, which can generate savings initially. However, over time (typically 2-3 years), these savings tend to diminish due to limited employee buy-in and the absence of an adequate energy management system.

EnFana’s approach to energy management begins with engaging employees from the outset, making energy efficiency a natural part of daily business practices for sustainable, long-term results. We address common challenges, such as the need for staff training to identify energy losses, hesitancy to adopt new practices, and the risk of disruptions to business operations.

In Stage 3, Our Team Will:

Common Challenges & EnFana’s Approach

- Challenge: Limited staff expertise in identifying energy inefficiencies

Solution: Hands-on training to help employees spot energy losses as part of their tasks, building organization-wide awareness. - Challenge: Team resistance to adopting new practices

Solution: Customized training and motivational strategies that secure employee buy-in. - Challenge: Potential business disruptions during project implementation

Solution: Risk assessment and planning for energy efficiency projects to prevent business disruptions, allowing energy-saving measures to integrate seamlessly into operations.

With EnFana, energy savings are not just a one-time achievement—they’re sustained through ongoing employee involvement, accountability, and a company-wide commitment to efficiency.

Step 4: Implementation of Energy-Saving Activities

Successful implementation of energy efficiency projects requires careful planning to avoid cashflow disruptions, achieve projected savings, and ensure employee buy-in.

In Stage 4, Our Team Will:

Common Challenges & EnFana’s Approach

- Challenge: Cashflow limitations for improvement projects

Solution: EnFana provides planning tools to help structure energy improvement projects, minimizing cashflow disruptions and ensuring projects are financially manageable. - Challenge: Energy efficiency projects may not achieve the projected energy savings

Solution: Our EnMS includes robust savings verification strategies, allowing you to track and confirm the effectiveness of energy efficiency projects. - Challenge: Resistance from workers to adopt process changes

Solution: EnFana offers methods for strategic implementation and tailored training that foster employee buy-in, making it easier for teams to adapt to new practices. - Challenge: Training for process changes might take too long

Solution: Our practical training program and agile project methodology, ensures that energy-saving measures are integrated efficiently. - Challenge: Difficulty in finding specialized vendors and suppliers

Solution: EnFana provides guidance on identifying and evaluating reliable vendors and suppliers, connecting you with the right partners to support your energy efficiency goals.

EnFana’s EnMS deployment supports a smooth implementation of energy-saving projects, from funding and training to vendor selection, ensuring that each project maximizes savings and operational efficiency.

Step 5: Monitor & Sustain Improvements

Sustaining improvements is essential for long-term energy efficiency. EnFana’s EnMS program helps companies transition naturally to this phase by embedding a culture of continuous improvement from day one.

In Stage 5, Our Team Will:

Common Challenges & EnFana’s Approach

- Challenge: Limited knowledge of energy Key Performance Indicators (KPIs)

Solution: EnFana will train your staff on KPI management and data analytics, empowering teams to drive measurable improvements. - Challenge: Absence of a continuous improvement culture

Solution: Our EnMS integrates continuous improvement practices into daily operations, fostering a culture where energy efficiency is an ongoing priority. - Challenge: Limited time for additional paperwork and reporting

Solution: EnFana utilizes digital automation tools to streamline data collection and reporting, minimizing the time and effort required for tracking energy performance.

With EnFana’s support, organizations can sustain energy-saving initiatives through KPI-driven improvements, an embedded culture of efficiency, and streamlined, automated reporting processes.

Case Study – Frozen Food Plant

A 25,000 sq. ft. frozen food plant with 280 employees faced high energy costs totaling $1,024,561 per year, which impacted its ability to stay competitive. The client engaged EnFana to help reduce energy expenses. Then, the analysis revealed that refrigeration accounted for 61% of total energy consumption.

EnFana developed a customized refrigeration maintenance plan and provided training to ensure the system operated at peak efficiency. Additionally, operational changes were implemented to further minimize energy consumption. As a result, the client achieved:

- Annual savings of $233,000 (22.8% of electricity costs)

- A 6.84% reduction in production costs

- A 4.9% improvement in uptime

- A decrease in GHG emissions by 802 tCO2 per year

Why Choose EnFana’s Energy Management System Program?

EnFana’s EnMS program offers a comprehensive, tailored solution for industrial and commercial clients aiming to reduce their energy footprint, save on energy costs, and meet global standards like ISO 50001. From tracking and monitoring to cost-efficient solutions and employee engagement, EnFana provides end-to-end support to foster a culture of energy efficiency and continuous improvement. With EnFana’s accelerated EnMS deployment, you’ll achieve your energy reduction goals sooner and with significantly less effort.

Years of Expertise & Professionalism

Team of experienced consultants with versatile commercial & industrial experience.

Successful projects completed for automotive, textile, food, cable, real estate, & hospitality sectors.

Benefits of EnMS

Partner with Us for a Brighter Future

Contact EnFana today to start building a sustainable, cost-effective energy management system for your business. Together, we can pave the way to a more energy-efficient and environmentally responsible future.